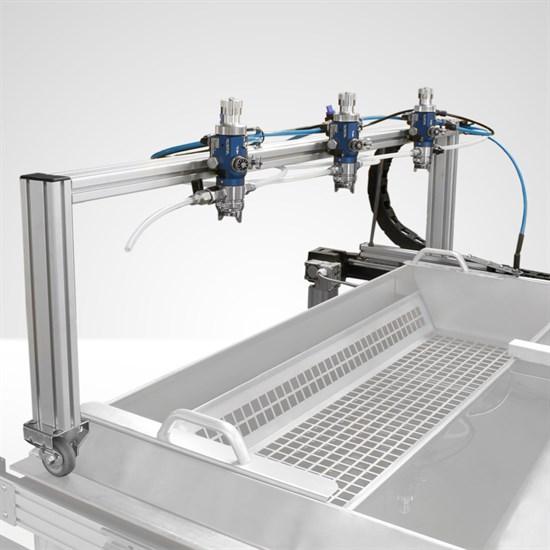

Water transfer printing Fully automatic activation unit for Big Dipper | 260 x 110 cm

Product description:

Fully automatic activation unit for Big Dipper 260x110cm:

simplifies the automatic activation unit and automates the process of activating the decorative films.

Procedure:

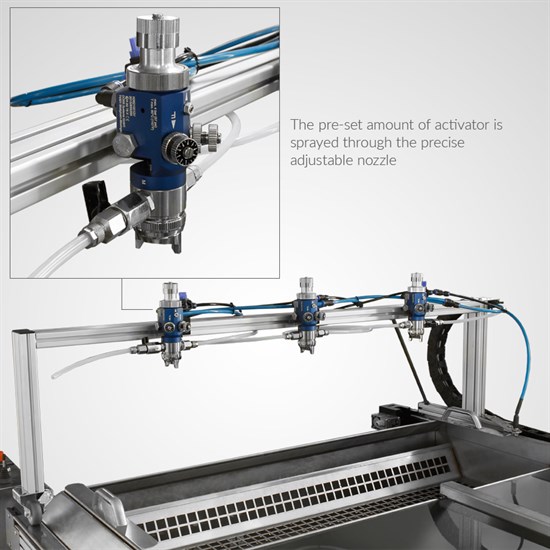

After placing the water transfer printing film, the activation button is pressed. From this moment, the automatic activation is running. After the soaking period, the automatic activation unit runs over the film and sprays the amount of activator, that you have selected. After the spraying process, the activating unit automatically returns to the starting point and the dippr begins with the automatic dipping process. After dipping process the diver arm moves at a comfortable height so you can remove the dipping frame and put another one in. The wash cycle can begin now, so you can start a new process.

Your advantage:

- Always consistent quality through constant amount of activator and soaking time of the film and therefore no dependence on employees

- During the automatic dipping process, you can already prepare the next steps

- Sales volume increases tremendously

- Precise adjustment of the waiting period, activator amount, diving speed for a perfect dipping.

Customer reviews 0

Write now your personal experience with this article and help others with their purchase decision

Log in and write a review